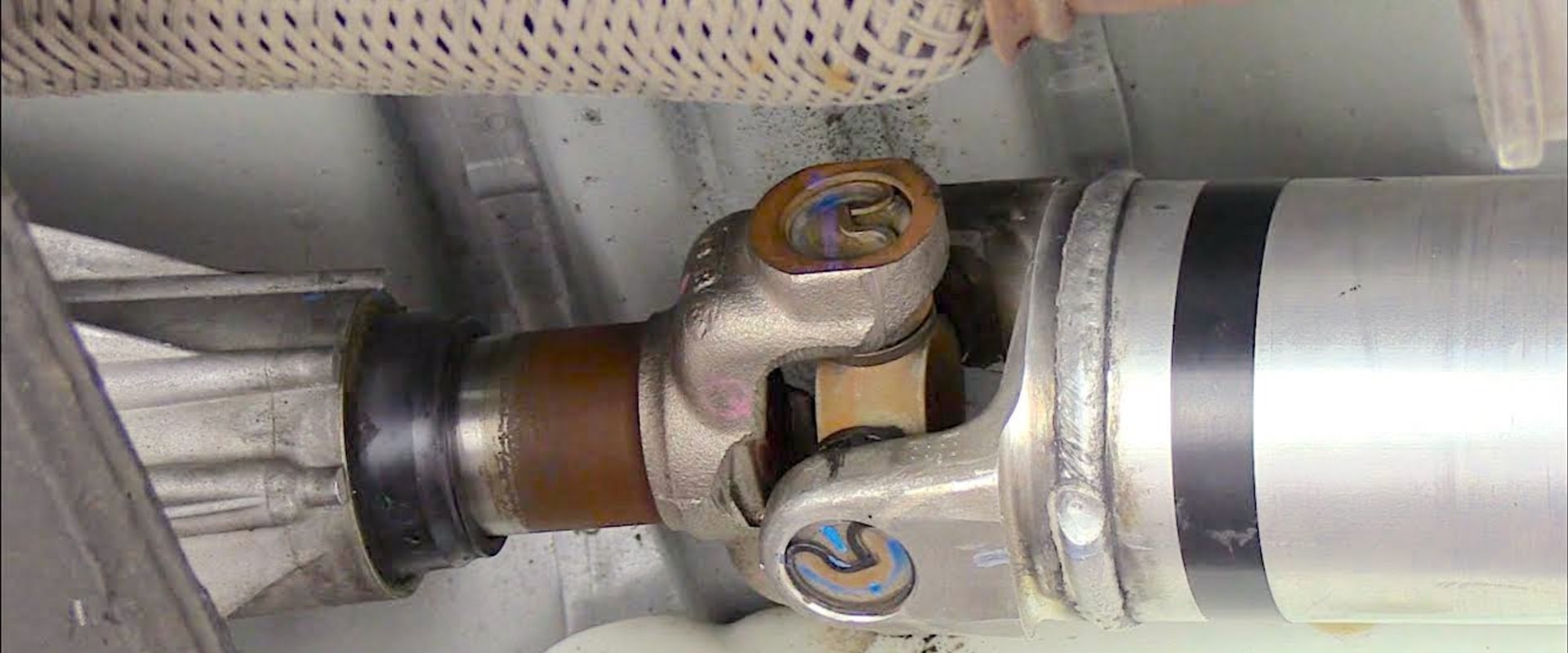

For efficient operation, it is important to regularly inspect the driveshaft at our Tire Shop in Charleston SC. The yokes with loose ends, excessive radial clearance, the radial clearance of the sliding groove, the bent shaft tube, or the lack of plugs in the sliding fork can cause transmission failure. The angle of the driveshaft of a vehicle with standard suspension and height is probably not a problem. In a vehicle that has had some type of suspension modification done, you could run into a problem. When you check the angle, make sure that the vehicle's wheels are resting on the ground or on a built-in lift.

Check the angle with the appropriate angle measurement tools. The angle should be in the range of three to eight degrees, depending on the rpm of the shaft. The higher the spindle rpm, the lower the grade should be. If the angle is greater than this, you may have vibration problems and premature joint wear.

It is also important to measure the angle of a two-piece axis. Regular driveline inspections and maintenance are essential if you want to keep your car and your life moving. This noise should be considered normal, and attempting to repair it will not result in a satisfactory reduction in transmission noise.